XBC - BACKWARD CURVED FANS

XBC - BACKWARD CURVED FANS

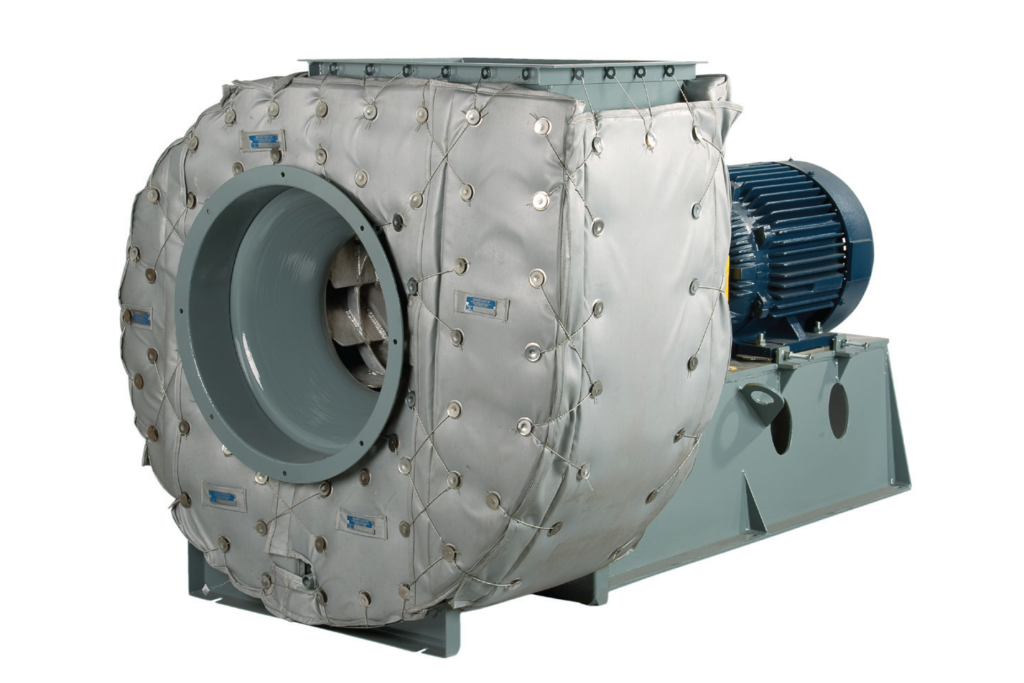

Highly efficient centrifugal fan, with superior static pressure capability.

Designed for longevity in clean industrial process applications.

Primary Applications

TYPE XBC centrifugal fans are non-overloading and suited for a wide range of industrial applications which include:

- Air pollution control

- Boiler applications

- Industrial process air

- Spray dryers

- Combustion air supply

- Heat recovery

- Waste to energy and incineration

About XBC - BACKWARD CURVED FANS

Wheel Specifications

Maximum flow (ACFM): 5000-300,000 SWSI 10,000 – 500,000 DWDI

Maximum pressure: 40 in. wg

Maximum Temperature: 1,200ºF

Static efficiency: 84%

Material Handling: none to dry & very light particulates

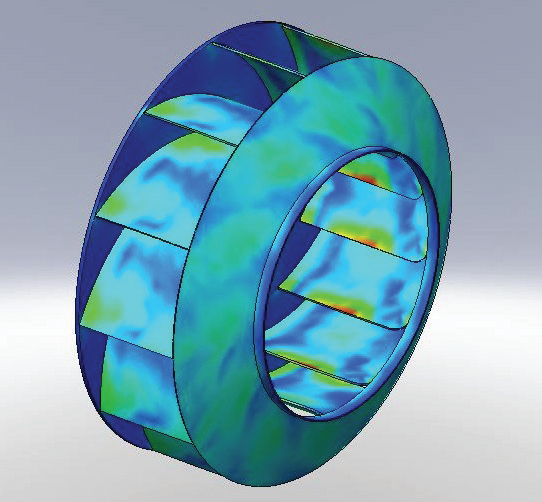

Wheels utilize heavy gauge backward curved blades. Efficiency equal or greater than backward inclined and airfoil with superior static pressure capability. Easily made of special alloys. Standard catalog sizes from 270 (27” Dia.) to 730 (73” Dia.), custom sizes available.

Item Details

Highly efficient centrifugal fan, with superior static pressure capability. Designed for longevity in clean industrial process applications.

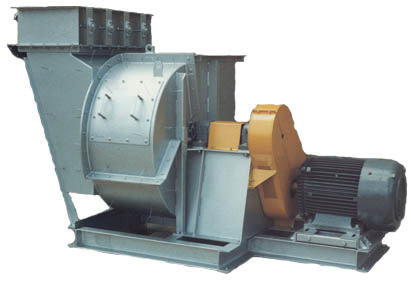

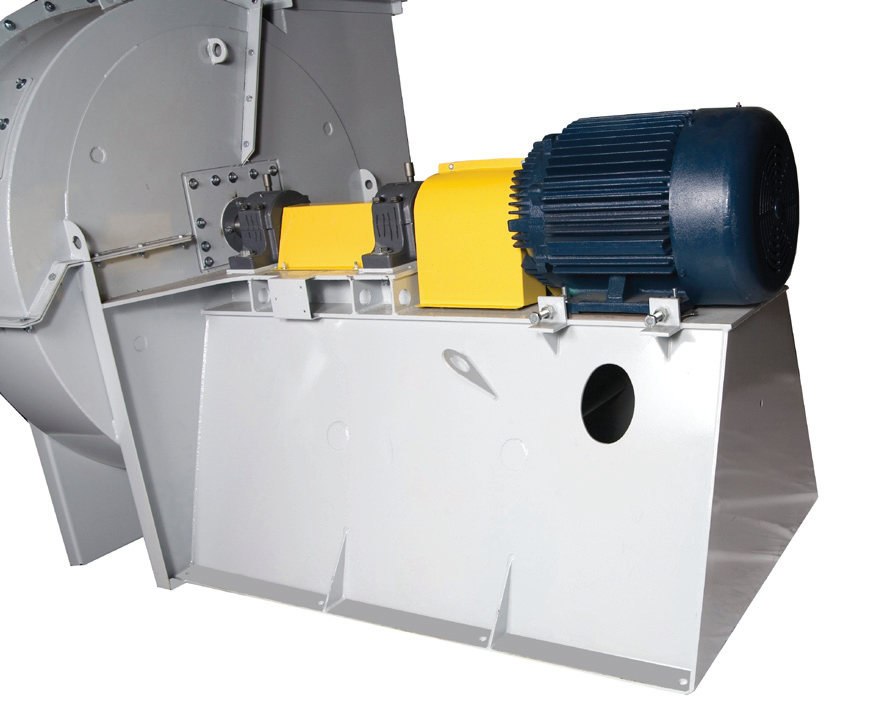

Type XBC backward curved fans have single-thickness, heavy-gauge backward curved wheel blades. XBC fans utilize the same continuously welded heavy-gauge housing configuration as the backward inclined and airfoil fans, but with heavier structural material and reinforcement to accommodate higher static pressure capabilities. All-welded fan construction, braced with structural steel shapes, reduces vibration and noise while providing smooth operation. XBC fans are available in single (SWSI) and double (DWDI) width and inlet.

TYPE XBC centrifugal fans are non-overloading and suited for a wide range of industrial applications, which include: AIR POLLUTION CONTROL, BOILER APPLICATIONS, INDUSTRIAL PROCESS AIR, SPRAY DRYERS, COMBUSTION AIR SUPPLY, HEAT RECOVERY, WASTE TO ENERGY, and INCINERATION.

XBC backward curved fans combine the benefits of both the airfoil and backward inclined style fans. Backward inclined fans run at slower speeds to develop the same static pressure as airfoil fans, while airfoil fans are structurally stronger than flat-bladed backward inclined fans. IAP combined the benefits of both in developing the XBC with single-thickness die-formed curved rigid blades in a wheel with a spun shroud that is coupled with an aerodynamically spun inlet cone for superior efficiency and high static pressure capability.

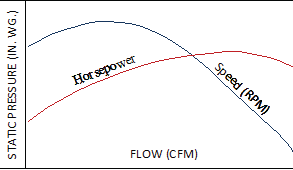

BACKWARD CURVED FANS ARE NON-OVERLOADING TO FREE DELIVERY, DEVELOPING HIGH STATIC PRESSURES WITH SUPERIOR STATIC EFFICIENCY

Fans with blades slanted away from the rotational direction of wheel travel, as the XBC has, are considered non-overloading. As the point of operation moves further down and to the right on the fan speed curve, horsepower consumption peaks and then reduces to the point of WOV. Therefore, if system resistance (static pressure) drops, horsepower consumption changes only slightly or is reduced.

FEA (Finite Element Analysis) of the XBC wheel insures integrity and reliability of design.