ICA - INLINE CENTRIFUGAL AIRFOIL FANS

ICA - INLINE CENTRIFUGAL AIRFOIL FANS

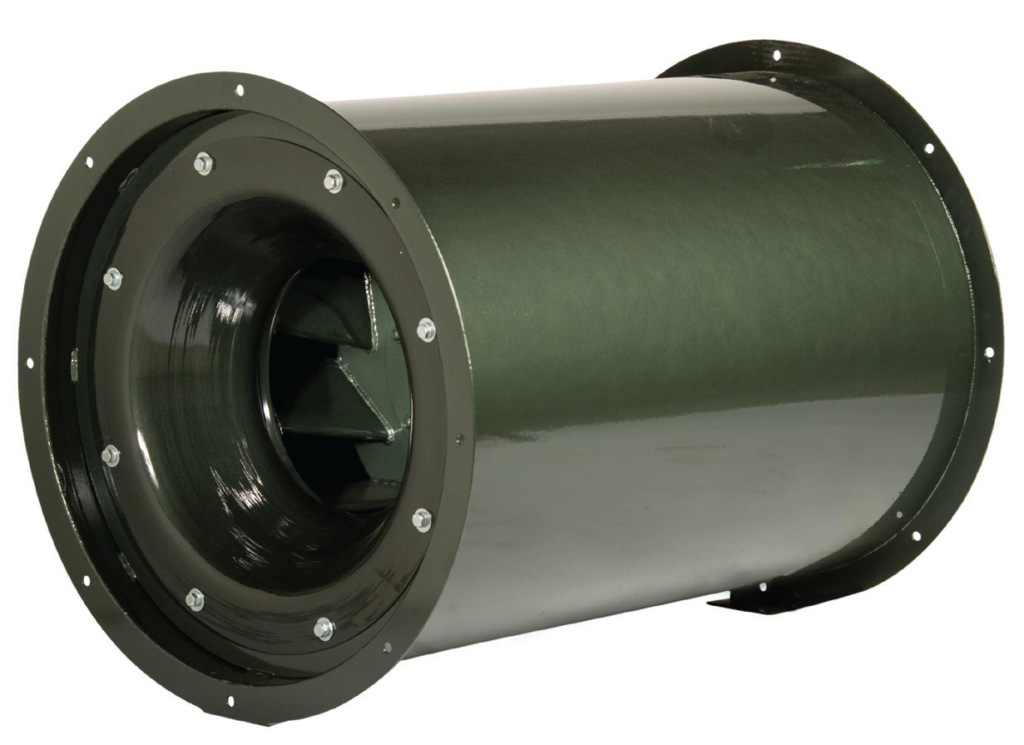

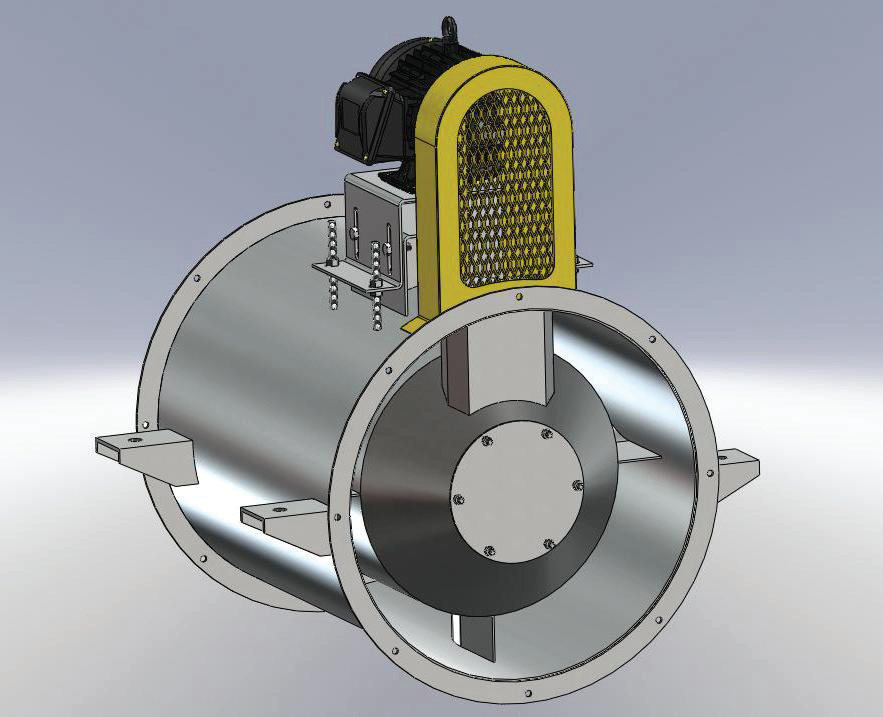

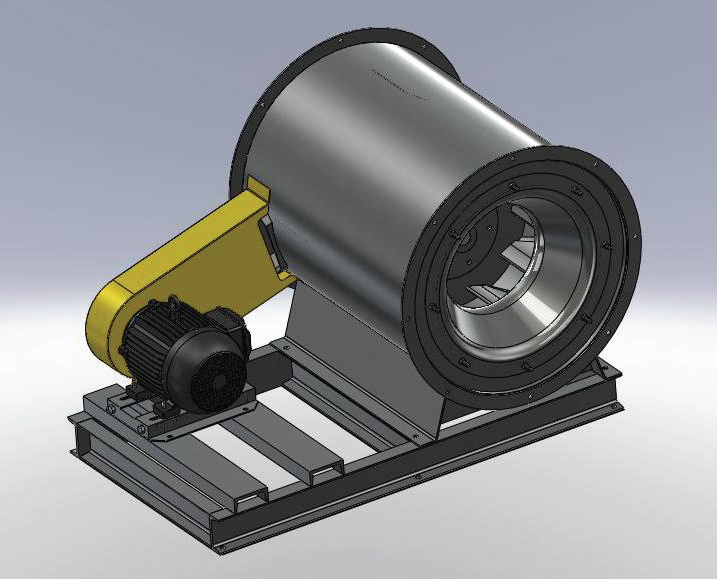

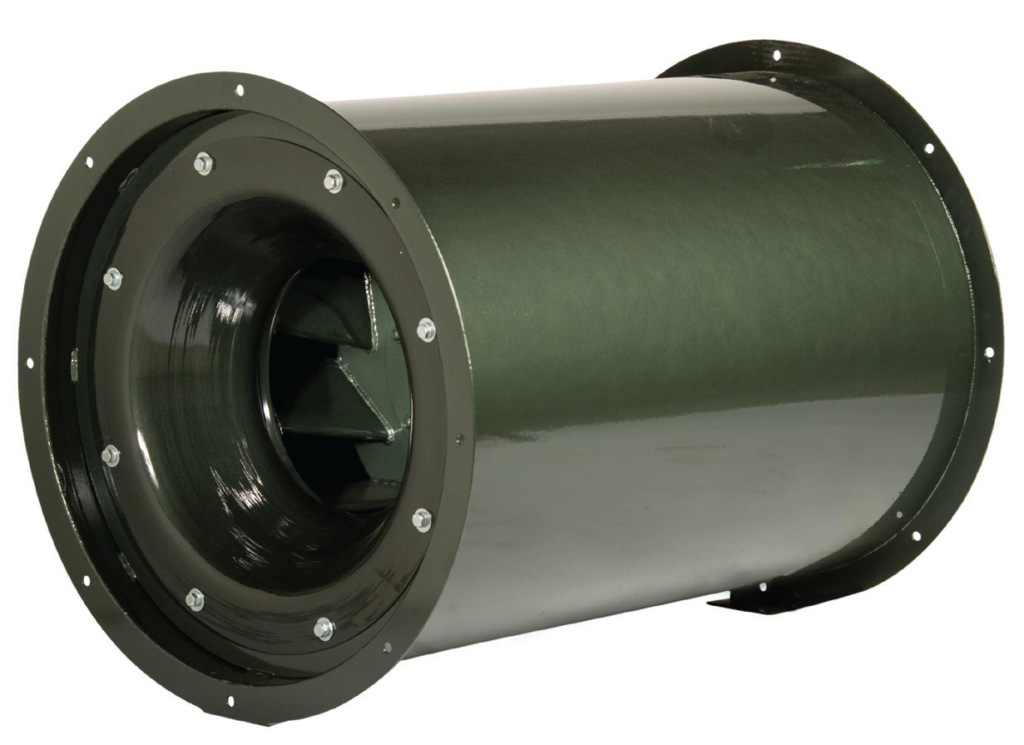

The type ICA is an inline fan with a centrifugal wheel. ICA fans combine the effi ciency of a centrifugal airfoil wheel with the compactness of a tubular fan housing; saving space while reducing horsepower consumption and operating costs.

Primary Applications

ICA fans are non-overloading and suited for a wide range of clean air industrial applications which include:

- Ventilation Supply & Return Air

- Exhaust Air

- Heating

- Ventilating & Cooling

About ICA - INLINE CENTRIFUGAL AIRFOIL FANS

Wheel Type Specifications

Maximum flow (ACFM): 3,000 – 150,000 SWSI

Maximum pressure: 12 in. wg

Maximum Temperature: 850ºF

Static Efficiency: 70%

Material Handling: no

Hollow double thickness airfoil blades. Centrifugal wheel design in tube housing develops higher pressures than standard axial fans. Tube housing allows for continuous runs of duct work without elbow interruption. Standard catalog sizes from 182 (18.25” Dia.) to 730 (73” Dia.) with custom sizes available.

Item Details

The type ICA is an inline fan with a centrifugal wheel. ICA fans combine the efficiency of a centrifugal airfoil wheel with the compactness of a tubular fan housing; saving space while reducing horsepower consumption and operating costs.

ICA fans incorporate continuously welded heavy gauge housings, smooth venturi spun inlet cones and highly effi cient wheels with airfoil blades & aerodynamic spun shrouds. Motor supports are comprised of rigid formed steel plate with adjustable motor mounting plate for belt tensioning. Rigidly constructed bearing and shaft tube support is provided with a removable end plate for bearing, shaft and sheave access.

The design and construction of the ICA fan family allows for highly efficient air movement with higher pressure capability than traditional axial & propeller inline fans. The ICA fan is also available in a vertical stack or roof mount with and without curb cap, wind band and butterfly back draft outlet damper.

ICA wheels incorporate a back plate with a smaller diameter than the front shroud coupled with tapered blades. This feature allows for smoother airflow in the fan housing as air coming off the blade tips is pre-angled in the direction of fl ow eliminating a 90° airflow turn at the blade tip required by other units on the market. Benefits of this feature include elimination of turbulence, improved efficiency, and lower noise levels than competitors’ designs.

ICA fans are non-overloading and suited for a wide range of clean air industrial applications which include:

- Ventilation Supply & Return Air

- Exhaust Air

- Heating

- Ventilating & Cooling