BPG, FPG, OPG & XPG - PLUG FANS

BPG, FPG, OPG & XPG - PLUG FANS

A versatile and compact fan design solution for circulating air and maintaining a constant temperature gradient. IAP Plug Fans are a durable, efficient and economic choice for a wide range of industrial applications.

Primary Applications

IAP Plug Fans offer a durable, efficient, and economic solution for various industrial applications, such as:

- Ovens

- Furnaces

- Kilns

- Dryers

- Space Heaters

- Spray Booths

- Air Curtains

About BPG, FPG, OPG & XPG - PLUG FANS

Wheel Type specifications

Four wheel designs to choose from:

BPG with backward inclined wheel for highest efficiency selections. -Type A Airfoil

Maximum flow (ACFM): 1,600-375,000 SWSI 2,400-675,000 DWDI

Maximum pressure: 24 in. wg

Maximum Temperature: 1,000ºF

Static Efficiency: 82%

Material Handling: none to dry & very light particulates

FPG with forward curved wheel for moving large capacities at low speeds.

Maximum flow (ACFM): 1,000 – 250,000 SWSI 1,200-400,000 DWDI

Maximum pressure: 8 in. wg

Maximum Temperature: 1,650ºF

Static Efficiency: 60%

Material Handling: no

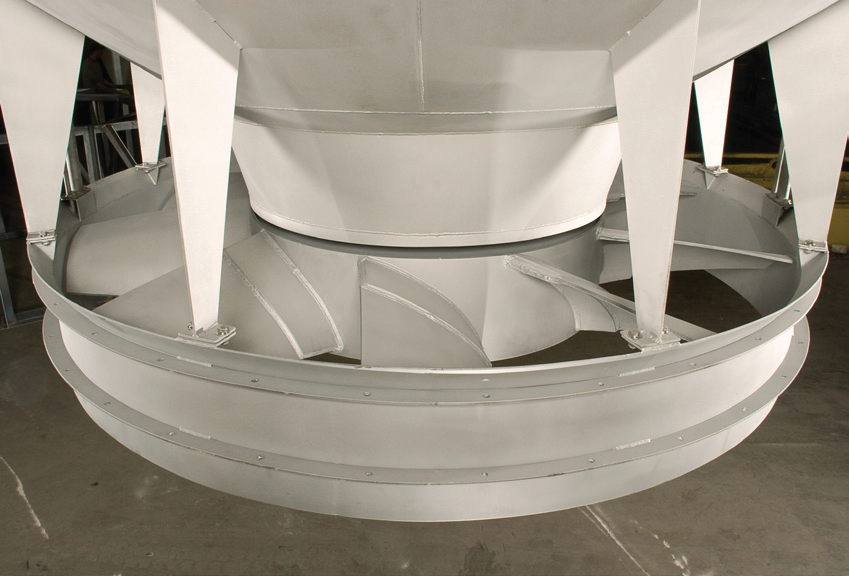

OPG with open radial blade for severe high temperature applications offers the strongest structural design.

Maximum flow (ACFM): 40 in. wg

Maximum pressure: 200-175,000 SWSI

Maximum Temperature: 2,000ºF

Static Efficiency: 68%

Material Handling: moderate to heavy particulates

XPG with axial prop for moving large capacities in severe high temperature applications.

Maximum flow (ACFM): 10 in. wg

Maximum pressure: 500 – 175,000 SWSI

Maximum Temperature: 850ºF

Static Efficiency: 65%

Material Handling: no

IAP Plug Fans can be fitted with four wheel designs to suit different performance needs. Airfoil (BPG) delivers smooth, efficient airflow at higher speeds with reduced horsepower. Forward Curved (FPG) moves large volumes of air quietly at low speeds and handles elevated temperatures well. Radial (OPG) provides strong structural durability, ideal for moderate pressures and wear liners with excellent temperature capacity. Vax (XPG) uses aerodynamic propellers with guide vanes for maximum efficiency, moving high air volumes at moderate pressures with greater capability than standard axial fans.

Item Details

A versatile and compact fan design solution for circulating air and maintaining a constant temperature gradient. IAP Plug Fans are a durable, efficient and economic choice for a wide range of industrial applications.

• Capacities to 300,000 ACFM with static pressures to 20 in. wg.

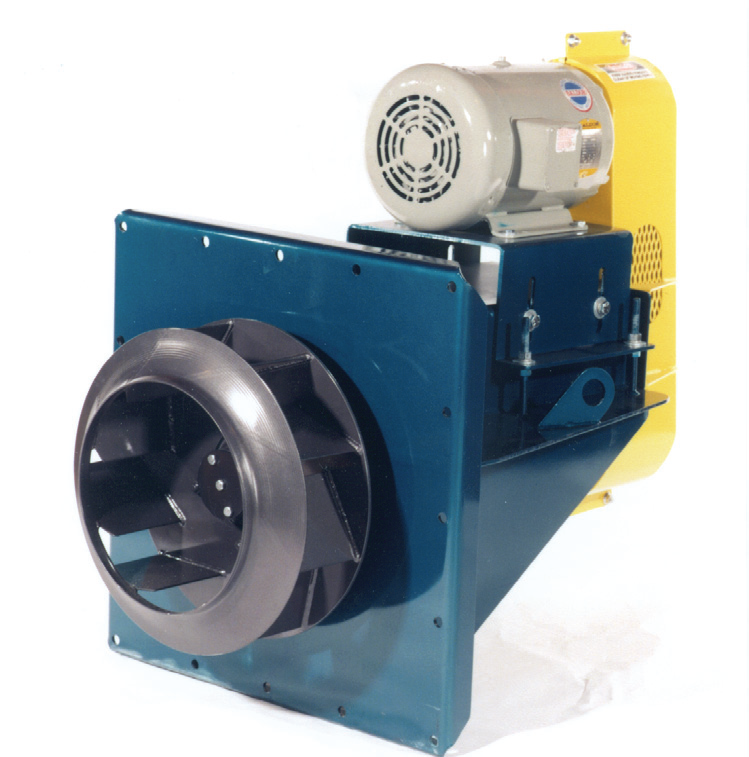

• A space saving solution for horizontal or vertical mounting.

• Elevated temperature construction from standard 300°F to 1800°F with upgrade packages for isolation and alloys of construction.

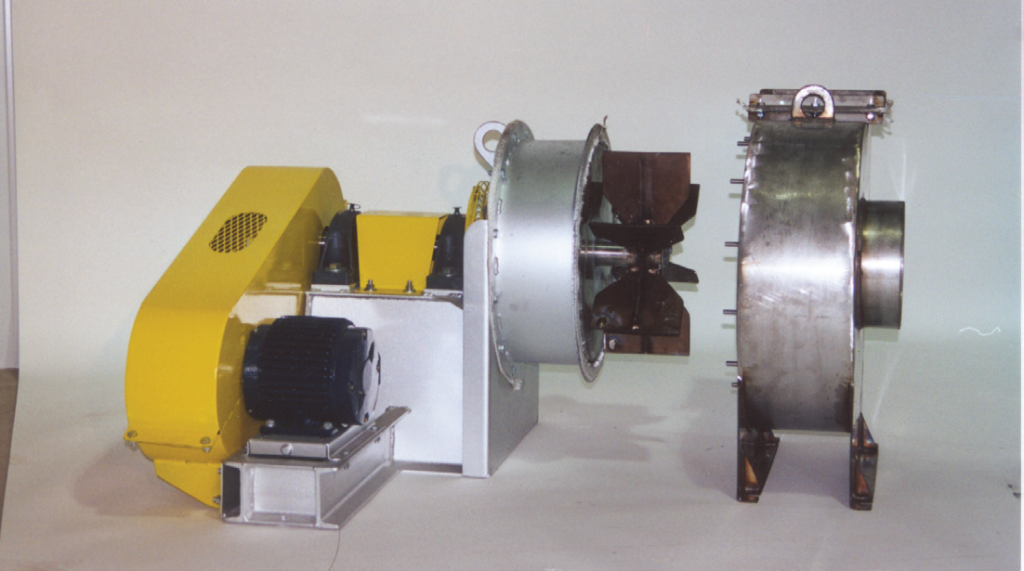

Most applications utilize the system plenum as the fan housing which reduces space requirements and ductwork connections, however, fan housings are available as an option to any IAP plug fan.

Adjustable motor base, removable guards and readily accessible bearings reduce maintenance time. Motor and drive assembly are mounted to a formed steel plate plug panel with flanges and cross-frame bracing for strength and flatness. Plug panel is pre-drilled and all units are factory assembled and balanced ready to “plug” into your supply, exhaust or recirculation system. Unit shown to the left is a floor mount option with round plug and detachable housing.

Four wheel designs to choose from: BPG with backward inclined wheel for highest efficiency selections. FPG with forward curved wheel for moving large capacities at low speeds. OPG with open radial blade for severe high temperature applications offers the strongest structural design. XPG with axial prop for moving large capacities in severe high temperature applications.

IAP Plug Fans offer a durable, efficient, and economic solution for various industrial applications, such as:

- Ovens

- Furnaces

- Kilns

- Dryers

- Space Heaters

- Spray Booths

- Air Curtains